产品详情

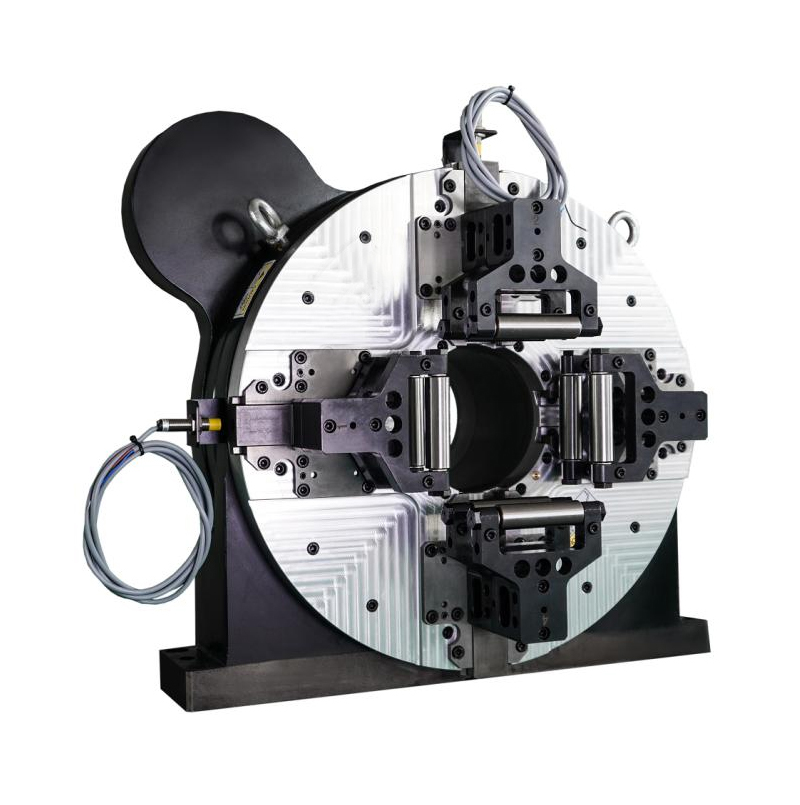

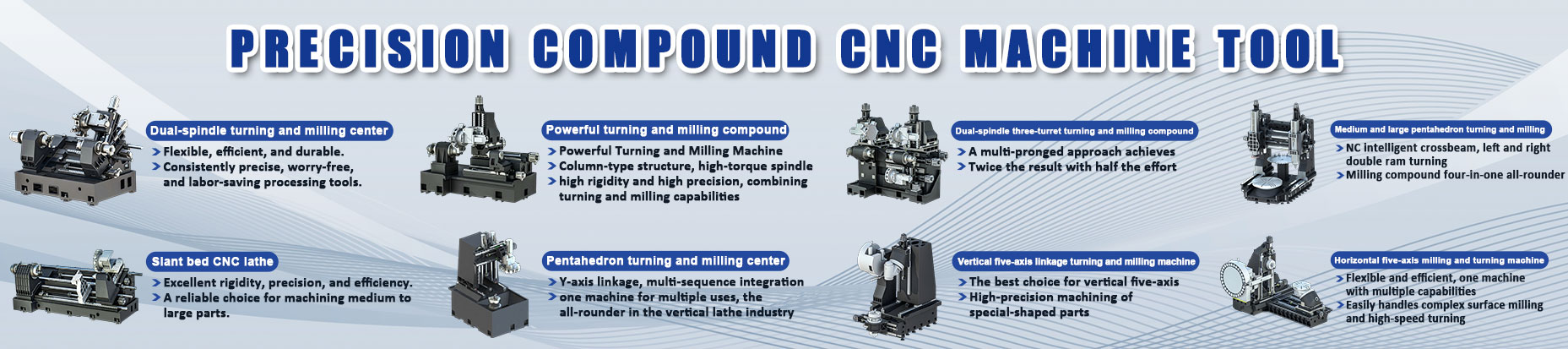

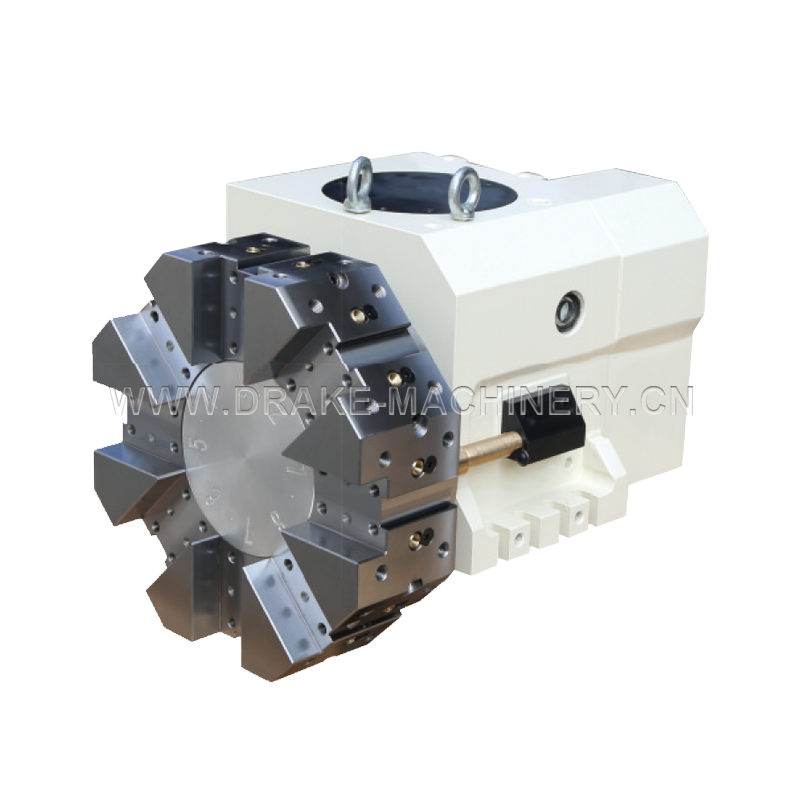

Y轴刀塔采用扁平结构,Y轴伺服电机通过滚珠丝杠驱动动力刀盘沿Y轴方向移动,适用于钻孔、铣削、车削、镗孔、螺纹切削等加工。

1.刀塔采用箱体内置式、前后四线轨框架结构布局,体积小,刚性强。

2.Y轴伺服电机驱动精密滚珠丝杠,驱动动力刀塔沿Y轴方向移动,定位精度高。

3.刀塔采用伺服电机分度,双向近刀换刀,换刀速度快,效率高。

4.可正反切削,适用于正反转布局机床。

5.动力电机的配置,可实现钻孔、铣削、车削、镗孔、攻丝等复杂零件的加工。

6.三片式精密端面齿盘,定位精准,定位精度高,重复定位精度高。

7.刀板采用液压锁紧,刚性高,可靠性好。

产品型号

产品参数

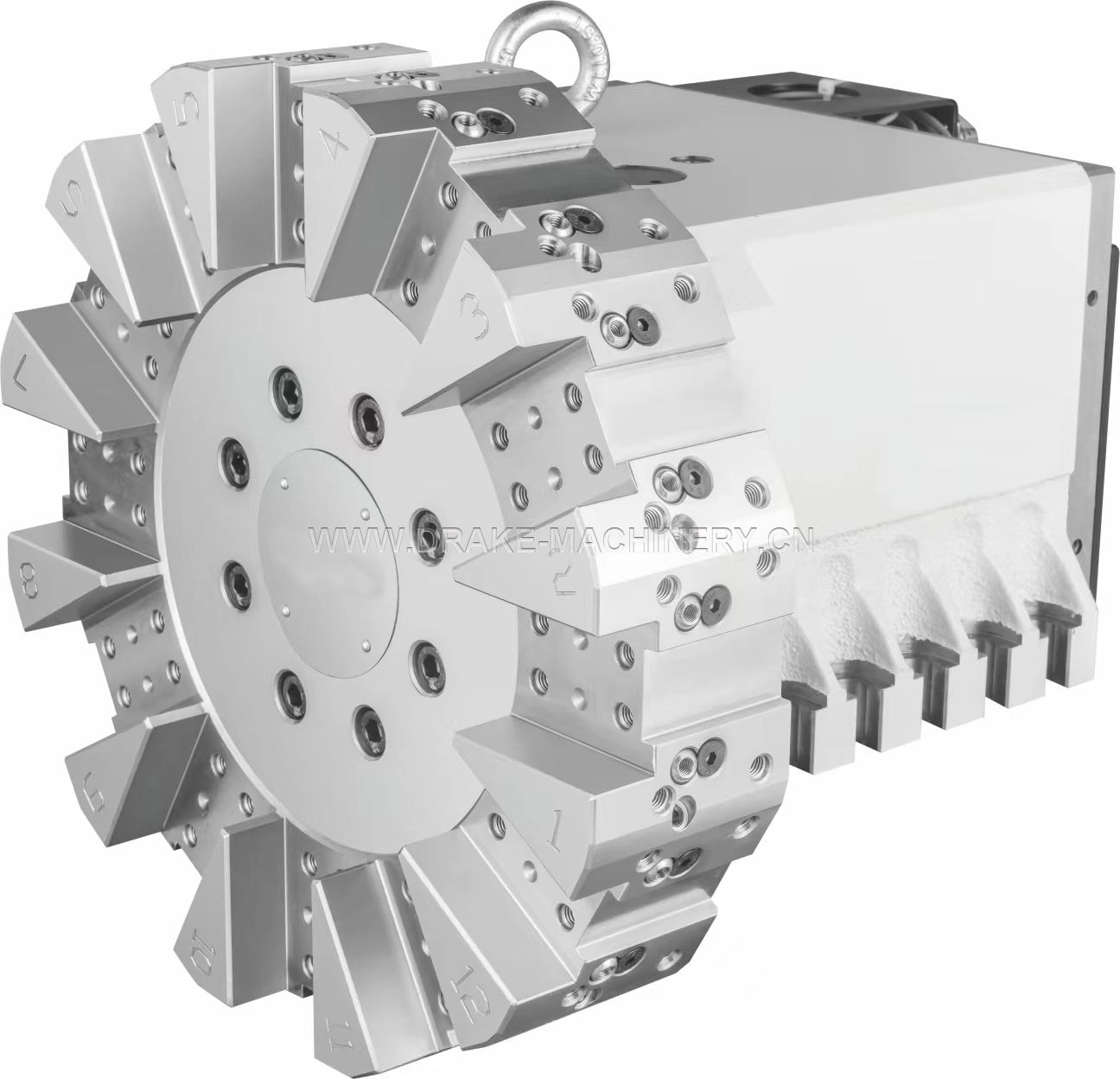

| Model | BMT | A | B | C | D | E | F | G | H | K | M | N | O | P | R | S | T | U | V1 | V2 | W | ||||||||||||||||||||||||||||||

| Y12-BMT40 | 40 | 127 | 35 | 70 | 137.5 | 75 | 368.5 | 213 | 480 | 35 | Φ17 | 25 | 7.5 | 123.5 | 38 | 262 | 127 | 8- 12 | 111 | 234 | 240 (Standard configuration) | 300 ( 15 workstations) | |||||||||||||||||||||||||||||

| Y16-BMT45 | 45 | 170 | 50 | 70 | 153.5 | 90 | 396 | 258.5 | 580 | 32 | Φ17 | 30 | 7.5 | 141 | 60 | 300 | 148 | 10- 12 | 132 | 293 | 290 | ||||||||||||||||||||||||||||||

| Y16-BMT55 | 55 | 70 | 151.5 | 100 | 394 | 261.5 | 340 | ||||||||||||||||||||||||||||||||||||||||||||

| Model | BMT | A | B | C | D | E | F | G | H | K | L | M | N | O | P | R | S | T | U | V1 | V2 | W | ||||||||||||||||||||||||||||||

| Y12H-BMT40 | 40 | 127 | 35 | 70 | 143 | 75 | 374 | 218.5 | 419 | 35 | 370 | Φ17 | 25 | 7.5 | 123.5 | 38 | 301 | 127 | 8- 12 | 111 | 234 | 240 (Standard configuration) | 300 (15 workstations) | |||||||||||||||||||||||||||||

| Y16H-BMT45 | 45 | 170 | 50 | 61 | 153.5 | 90 | 396 | 258.5 | 519 | 32 | 430 | Φ17 | 30 | 7.5 | 141 | 60 | 360 | 148 | 10- 12 | 132 | 293 | 290 | ||||||||||||||||||||||||||||||

| Y16H-BMT55 | 55 | 59 | 151.5 | 100 | 394 | 261.5 | 340 | |||||||||||||||||||||||||||||||||||||||||||||

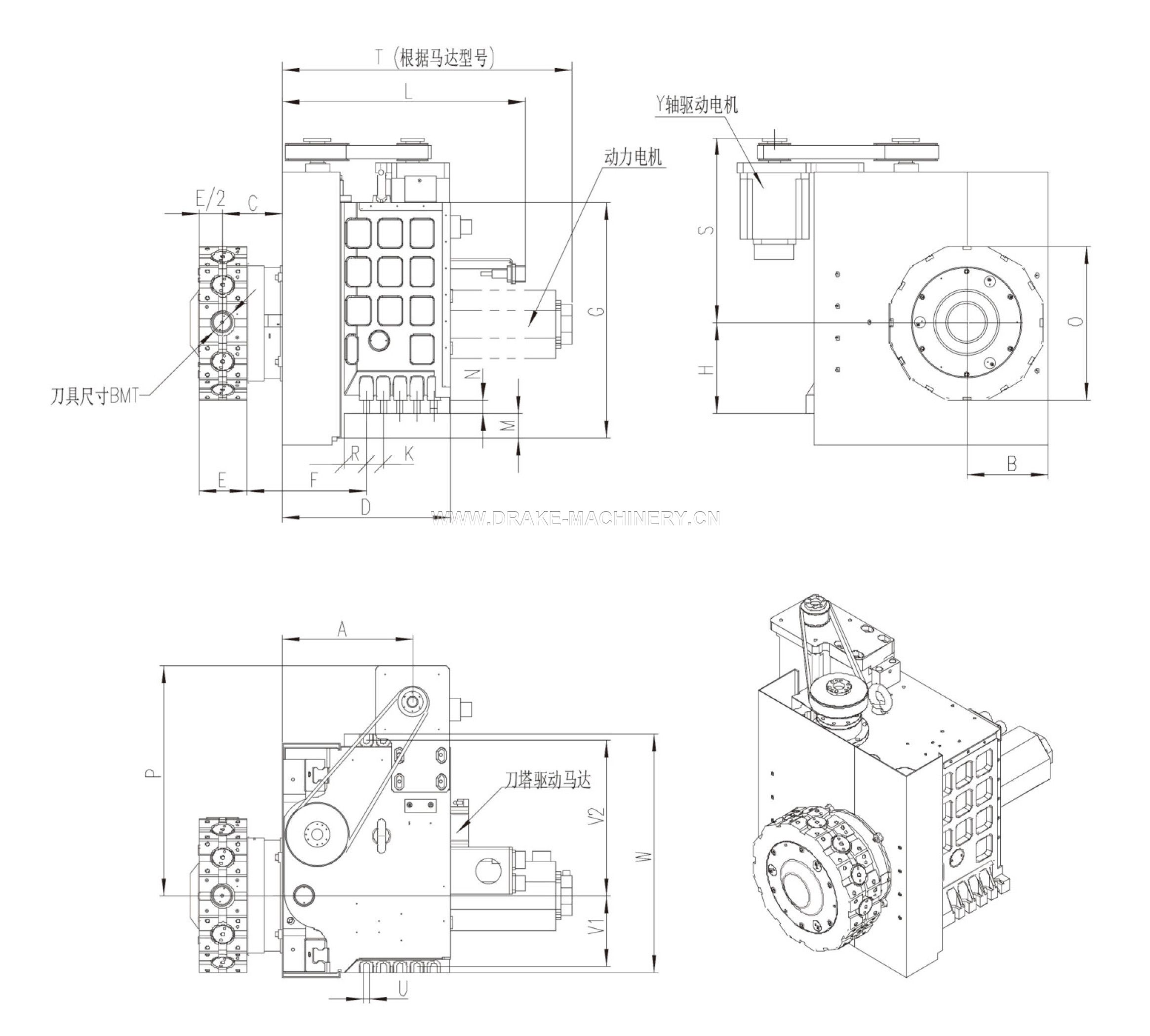

| MAIN SPECIFICATIONS | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Items | Unit | Y12 | Y16 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Number of work stations | 12/ 15 | 12 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Allowable tangential force for clamping time | KNm | 0.75 | 1.7 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Positioning indexing accuracy | sec. | ±4" | ±4" | ||||||||||||||||||||||||||||||||||||||||||||||||

| Repeatability | sec. | ±1.6" | ±1.6" | ||||||||||||||||||||||||||||||||||||||||||||||||

| 30° turning and braking time | s | 0. 1 | 0. 12 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Time per step excluding acceleration and braking | s | 0.06 | 0.07 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Hydraulic tool locking/unlocking time | s | 0. 11 | 0. 12 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Allowable tool change frequency | 次/Min | 25 | 20 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Allowable unbalance moment during machining | Nm | 16 | 32 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Operating pressure ±10% | Mpa | 5 | 5 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Coolant pressure value | Mpa | 2.5 | 2.5 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Weight (without tool) | Kg | 150 | 250 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Tool to motor drive gear ratio | 1:1 | 1:1 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Carrying tool holder specification | BMT40 | BMT45/BMT55 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Tool limit speed | rpm | 6000 | 5000 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Y-axis reduction ratio | 1:1.5 | 1:2 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Max. permissible feed speed | m/min | 10 | 10 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Allowable Y-axis feed stroke | mm | ±35 | ±50 | ||||||||||||||||||||||||||||||||||||||||||||||||

| Positioning accuracy | μm | 10 | 10 | ||||||||||||||||||||||||||||||||||||||||||||||||